Light steel structures fully comply with the requirements of Building Regulations and leading warranty providers as well as reducing the fire load in residential developments. Steve Thompson Managing Director for light steel frame specialists EOS, discusses the benefits of using a complete and compliant construction system.

The government are discouraging the use of flammable materials in external walls. The delay in responding to its 2020 consultation proposing to extend the combustibles ban currently at 18 metres added uncertainty to specification decisions. According to a poll of the industry undertaken by the NHBC last year, fewer than three in 10 housebuilders expect to use timber frames.

A key advantage of light steel frame is fire performance. The amount of combustible material in a light steel framed building is much lower, therefore the fire risk during construction and when in use is vastly reduced. Steel is non-combustible and does not add to the fire load – reducing the 'fuel for the fire' and limiting risk of damage and injury. This risk is further decreased by replacing some combustible materials with a concrete or screed deck on a steel frame.

Making the Building Process Inherently Safer

In her report 'Building a Safer Future', Dame Judith Hackitt recommends: "More effective testing regimes with clearer labelling and product traceability, in order to drive continuous improvement, higher performance and encourage innovative product and system design under better quality control."

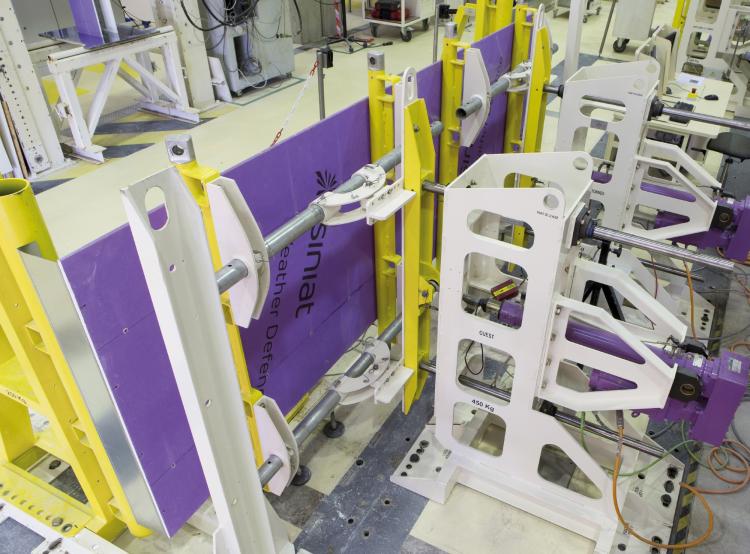

Current regulations typically deal with individual products and how they perform in laboratory tests. However, we believe material providers should have full-scale testing regimes that study the performance of products working together to see how they interact in 'real' circumstances, like under fire conditions or when exposed to wind and rain.

Fragmented supply chains also result in components being offered by a multitude of manufacturers, therefore warranties are complex, for very limited timescales or simply non-existent. This uncertainty also extends to the costs involved, the speed of build and the quality of the final outcome.

EOS as part of Etex are continually looking at ways to make the building process not only inherently safer and sustainable but also to offer performance assurances to architects, housebuilders and specifiers to ensure they can provide sufficient levels of protection to occupants.

Improving levels of occupants' safety and increasing the quality of the build need to be controlled and managed. But how can this be achieved without substantial and reliable test evidence?

Our research and perspective interviews with sector experts have equipped us with a deep understanding of the challenges faced by housing specifiers. A lack of performance testing is a major concern. When disparate building elements are brought together it is left to the specifier to assess whether the chosen combination of materials (boards, metals, insulation) will deliver the required levels of performance. A lack of test evidence and data creates real challenges for specifiers having to achieve precise safety and performance requirements.

Minimising Risks

Fire protection for light steel framing is typically provided by the use of non-combustible boards for internal linings and fire protection systems such as those manufactured by our Etex group partners – passive fire protection specialists, Promat and FSi who develop and manufacture a full range of built-in fire systems to protect infrastructure and assets. Fire resistance periods of up to 120 minutes are readily achievable.

Developed in collaboration with our Etex partners, Siniat, a leading expert in plasterboard and drylining, together with Promat and FSi – our complete loadbearing and non-loadbearing walling and flooring systems combine the technical and manufacturing expertise of the group to deliver a comprehensive range of tested and certified solutions for light steel frame construction – all from one supplier.

Our components and products are rigorously tested together to ensure compatibility and system performance. When walling and flooring systems are built entirely with Etex components and materials in line with our latest standards, after a validation process— we award a 30-year Etex warranty.

This approach mitigates risk because these integrated solutions have been tested as complete systems and assessed for compliance with the latest regulations and standards, to ensure robust and reliable performance. Design performance is achieved using combinations of boarding and insulation and only tested configurations are available for selection.

Currently in research and development, we are taking factory prefabrication and preassembly to the next level - adding windows, doors and cladding to our light steel frame panelised solutions. These unitised systems will have to go through our stringent testing protocols before being released to the market.

Technical Competence

The Hackitt report highlights failings within the construction industry and sets out recommendations for a major shakeup of the current regulatory framework governing building control and fire safety in residential buildings.

As manufacturers we take our responsibilities extremely seriously. We are committed to technical competence and as part of Etex, we have some of the best fire experts in the UK on our team. They work closely with certification bodies to jointly develop and design technical solutions.

Construction can be a complex business but as we evolve more advanced offsite technologies, we can help housebuilders reduce risk and operate with more certainty and confidence. Robust testing regimes backed by comprehensive warranties offer assurances to developers and help specifying teams safeguard building owners and occupants.

Steve Thompson

Managing Director

EOS Framing

Stay in touch: