Building safety is a key concern of the Light Steel Frame Association (LSFA), our members and end-clients. But safety does not have to come at the expense of sustainability – with light steel frame, construction professionals can achieve both. The LSFA is on a mission to highlight the safety and sustainability credentials of light steel – here we contrast and compare different metrics for assessing environmental impact.

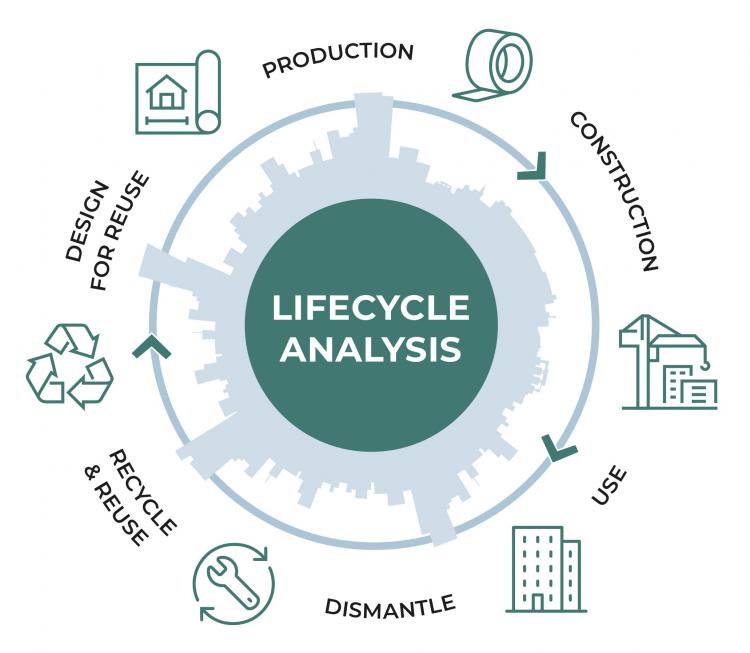

Once environmental discussions focused on lifecycle analysis including recycling buildings at the end of life. More recently the focus has been on embodied carbon. But this is only part of the sustainability equation. Embodied carbon assessment is a subset of a broader discipline of lifecycle analysis which covers a range of different environmental impacts.

To understand the environmental performance of a product, the LSFA and our members firmly believe its entire lifecycle needs to be taken into consideration – not just the manufacturing and construction phases. A lifecycle assessment of a steel product looks at resources, energy and emissions, from steel production to its end-of-life stage, including recycling or reuse.

As the construction industry continues to prioritise safe and sustainable building solutions – light steel framing has become an increasingly attractive option. This type of steel framing offers several environmental advantages that make it well suited for numerous applications in both residential and commercial buildings.

National targets for carbon emission reductions and the drive for buildings that are ‘low carbon’ in operation present a huge challenge to the construction industry – a challenge which the steel construction sector is playing a major part in overcoming.

In addition to being strong and economical, light steel frame systems also provide excellent thermal insulation properties due to their airtight nature – reducing in-use carbon emissions for the lifetime of the building. The use of light steel also allows for more efficient insulation systems compared to other materials used in offsite technology portfolios. Lightweight metal studs create air pockets that can be filled with insulation which helps reduce heat loss through walls or roofs and increases thermal efficiency within a structure’s envelope.

These structures require fewer resources to build and maintain while providing greater durability over time, they have longer lifespans resulting in lower long-term costs associated with maintenance and repairs. In addition, the frames have exceptional acoustic performance which makes them suitable for use in areas where noise pollution needs to be reduced or eliminated altogether.

Overall, light steel provides many environmental benefits. Its low weight facilitates easy transport, reduced foundation requirements and prefabrication means it is quick to assemble on site. Its ability to support multiple types of finishes makes it suitable for a variety of cladding options allowing architects greater scope in their designs without compromising sustainability goals. In addition, its excellent thermal properties offer significant potential savings in terms of heating and cooling costs throughout the lifespan of light steel buildings.

Manufactured from the most abundant component on earth, steel can be recycled or reused endlessly without detriment to its properties. This unique characteristic gives steel a high value at all stages of its lifecycle. The recovery infrastructure for steel recycling is highly developed and extremely efficient and has been in place for decades. Current recovery rates from demolition sites in the UK are 99% for structural steelwork and 96% for all steel construction products – figures that far exceed those of any other building material.

Site waste is virtually eliminated by the use of prefabricated light steel systems compared to the industry average wastage of 10% in construction materials. Cold rolled steel components are manufactured to length, the swarf and offcuts produced which are minimal, can be recycled so there is no production waste.

Light steel frame construction is used extensively in the UK in a wide range of developments. The overriding benefits of safety, quality, speed, strength and value are widely acknowledged but the sustainability benefits can be overlooked. As innovators in light steel systems, leading manufacturers within our membership want to inspire construction professionals to develop buildings that meet the rigorous requirements of the recent Building Safety Act but are also highly sustainable.

A lifecycle approach will be a ‘game changer’ for the light steel sector and long-term analysis will show that it is intrinsically more environmentally sustainability than other construction materials. Its properties make it the ultimate sustainable construction solution in terms of its longevity, superior in-use performance and its ability to be recycled and reused. But most importantly – enhancing the safety and sustainability credentials of new buildings.

The LSFA works to drive engagement, champion change, and spread the word about the cost, productivity, performance, sustainability and safety benefits of contemporary light steel systems. Trusted and widely specified by the UK construction industry – highly innovative and digitally savvy, the light steel sector has developed panelised and modular solutions that deliver high quality buildings on fast-track construction programmes. Bringing together a wealth of experience and technical know-how, the LSFA’s website has a library of valuable information, including guides on sustainable steel and circular construction. To download click here.

Stay in touch: