The light steel frame industry can play a vital role in achieving a circular economy, reducing the burden on nature by ensuring resources remain in use as long as possible. Chair of the Light Steel Frame Association (LSFA), Ben Towe – stresses why we need to move away from linear construction principles and embrace circularity.

100% Recyclable, Infinitely Reusable

You may ask what sets steel apart from other building materials in the circulatory debate?

Research carried out by the LSFA's technical partner, the Steel Construction Institute (SCI) estimates that there are around 100 million tonnes of steel in buildings and infrastructure in the UK. This 'stock' of steel is an important and valuable material asset that means we are largely self-sufficient in steel and can virtually produce all we need through recycling or reusing our latent stock to satisfy future market demand.

Steel has a unique characteristic as it can be reused and recycled repeatedly without losing its qualities as a building material. All steel used in today's construction projects has some recycled content. The constructional steelwork used in the UK contains an average of 60% recycled content.

The recovery infrastructure for steel recycling is highly developed and extremely efficient and has been in place for decades. Current recovery rates from demolition sites in the UK are 99% for structural steelwork and 96% for all steel construction products – figures that far exceed those for any other construction material.

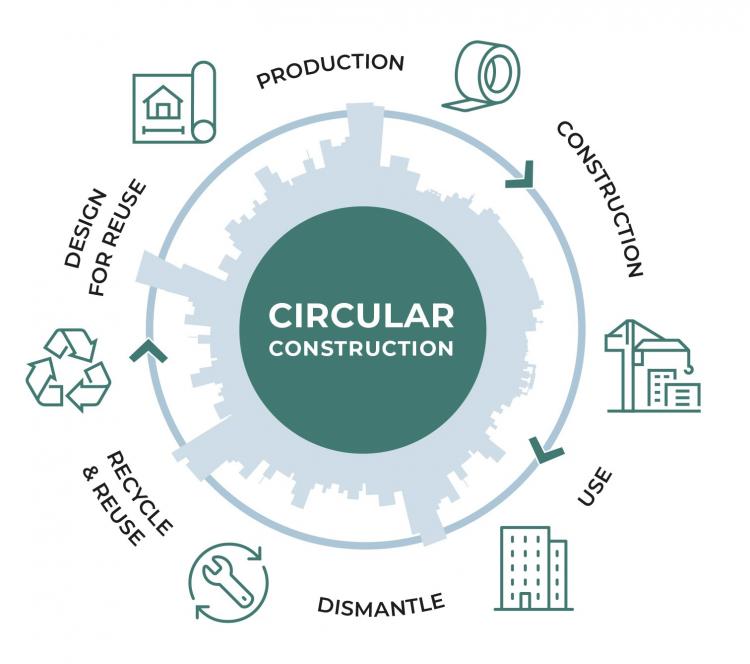

Steel is central to transitioning away from a linear approach – take, make, dispose, to circular construction – reduce, reuse, recycle, repeat and offers significant opportunities to mitigate the adverse impact on our environment. We need to adopt innovative approaches that design out waste, use resources more efficiently and keep materials and assets in use for as long as possible to retain their value by re-thinking the way that we design our homes and buildings.

Improving Economic Opportunities

A decade ago, the UK Green Building Council warned that 120 metric tonnes of waste was generated from construction, demolition and excavation – representing a staggering 59% of total UK waste. Whilst most construction waste is now diverted from landfill, outside the steel industry – little is being recycled or reused for the same or similar purpose.

But other countries are way ahead of the curve. The Netherlands for example, has set itself a target of having a 50% circular economy by 2030 and to be fully circular by 2050. But most governments have yet to realise the potential of the circular economy and the interrelated benefits to reduce ecological impacts whilst diversifying and improving economic opportunities.

Evolving the Value Chain

For circular economy principles to successfully work in the built environment, business models need to evolve across the entire value chain. Design optimisation is crucial in a circular construction approach and a lot of thinking has to be done up front. Once the architectural priority was form and function but now there are a raft of considerations coming to the fore such as design for longevity, adaptability and the offsite mantra of – Design for Manufacture and Assembly (DfMA). Moreover, it is imperative to plan for a building's 'end' right at the beginning of the design stage to enhance the sustainability value chain through Design for Disassembly (DfD), Design for Reuse (DfR) and recoverability protocols.

But where Design for Disassembly focuses on the eventual recycling of materials such as steel, Design for Reuse plans for the use of specific building components in similar projects during the design stage and requires comprehensive data capture and recording. The Design for Reuse model specifically pre-empts future use, so designs do not require adapting.

Capturing and recording performance, testing results, loading capabilities and even dimensions are vital to ensure any pre-existing systems fit within the design specifications and requirements of a new build in the future.

A Question of Time

Buildings should not only be inherently safe but should also be constructed to stand the test of time. In his recent challenging book 'Humanise' – Thomas Heatherwick states the most sustainable building is one that is designed to last a thousand years. Many light steel frame buildings are BOPAS certified for a design life of 60 years. But according to the SCI, design life predictions for light steel in a 'warm frame' environment is in excess of 250 years.

Robust, reusable, recyclable and adaptable – steel has excellent circular construction credentials. As a material it is strong and durable, as a structural framing system it is lightweight and cost efficient. Steel's material properties make it the ultimate sustainable construction solution – enhancing both the safety and sustainability credentials of light steel buildings.

Light Steel Frame Association

The LSFA works to drive engagement, champion change, and spread the word about the cost, productivity, performance and sustainability benefits of contemporary light steel systems. Trusted and widely specified by the UK construction industry – highly innovative and digitally savvy, the light steel sector has developed panelised and modular solutions that deliver high quality buildings on fast-track construction programmes. Bringing together a wealth of experience and technical know-how, the LSFA membership represents manufacturers, installers, industry supply chains, architects, engineers, consultants and clients operating in the light steel sector.

For more information and to download LIGHT STEEL & CIRCULAR CONSTRUCTION, visit:

Stay in touch: