Seismic II has been selected as one of the UK’s key demonstration projects in offsite construction.

It represents an important milestone in the industry’s journey towards Modern Methods of Construction (MMC). The project aims to prove that using standardised, mass-produced components delivers high quality, high performing buildings at better value.

We are focusing at first on the healthcare and education sectors, showing how hospitals and schools can be delivered more efficiently. But the learning from Seismic also lends itself to residential development and many other opportunities.

blacc is the lead partner on the Seismic consortium, which also includes offsite manufacturers Elliott Group and the McAvoy Group, Tata Steel, the Manufacturing Technology Centre (MTC), the Active Building Centre (ABC), and the National Composite Centre (NCC).

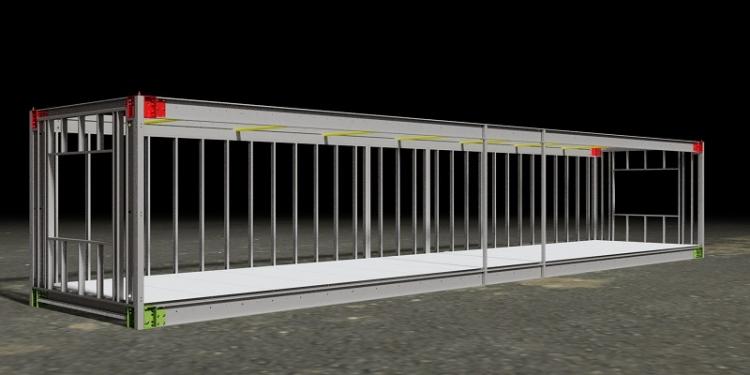

This project will build upon the success of Seismic I which showed how a standardised light steel frame improved the design and construction of schools. Seismic II will add to this by looking at the building fabric, developing wall, floor, ceiling and roof components that are interoperable with the frame.

The ultimate aim is the creation of a ‘kit of parts’ that can be easily configured to suit the specific requirements of the client.

Richard Crosby, director of blacc, said:

“The Seismic system is already proving the benefits of offsite construction in the schools sector and our componentised off-site schools solution has saved the country tens of millions. Unsurprisingly, we are gaining interest from many other sectors too, including housing and healthcare. With this additional investment we’re through to a whole new level of productivity, efficiency and materials innovation.

“blacc has brought together this new consortium to create standardised solutions for the whole building envelope. We are opening up manufacturing opportunities at scale that also enable us to look at new high-performance materials that are currently not considered in the construction industry.

“Through collaboration we are cutting costs, cutting carbon and creating major industrial opportunities in the North and Midlands. Everything about the Seismic project addresses the Government’s vision for construction post-coronavirus and genuinely allows us to build back better.”

Seismic II is one of three demonstration projects to receive funding this summer (July 2020) from UK Research and Innovation (UKRI) via its Transforming Construction challenge.

As well as improving offsite construction processes, Seismic II will look at the impact of this methodology on whole life performance.

Richard added: “Most traditional UK construction relies on bespoke systems created by individual manufacturers. A lack of standardisation leads to compatibility issues, causing errors, delays and defects.

“Adopting more modern methods of construction will be an essential part of the government meeting its targets to reduce costs and emissions within the sector and can also play its part in delivering better outcomes for building owners, operators and users.”